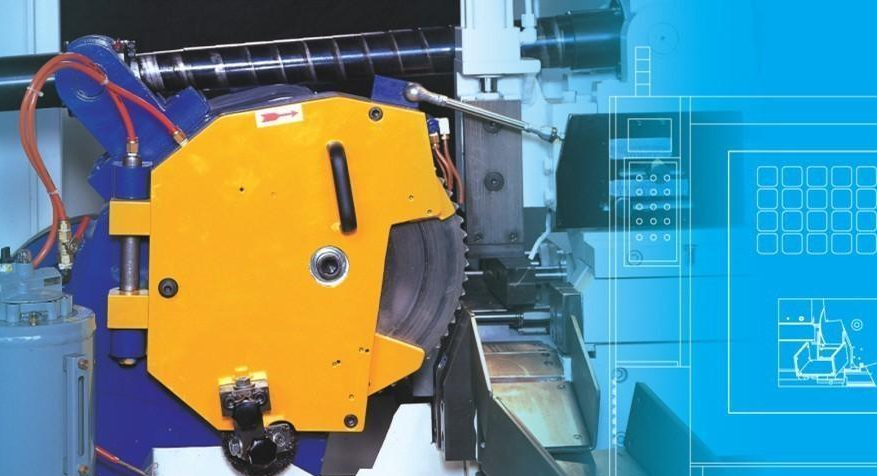

The four major sawing advantages of circular sawing machines. Circular sawing machine manufacturers tell you

1. More:

There are many types of workpiece materials for machine tool sawing, such as high-temperature alloys, nickel alloys, titanium alloys, stainless steel and other materials, which basically cover all the categories of metal materials at home and abroad, including all kinds of difficult-to-cut materials and easy-to-cut materials. Jingweite uses the heavy-duty TCT world-renowned imported circular saw blade from Japan's Denon. The saw blade feed rate per tooth is doubled, which greatly shortens the sawing time and improves the sawing efficiency.

2. Fast:

The feed speed of the machine tool is fast. Jingweite adopts the advanced new transmission method of the main drive servo motor to drive the gear box and the international advanced horizontal feed sawing method to ensure the stability, efficiency and accuracy of the sawing process. The sawing efficiency is high, which is one to two times higher than the existing machine tools.

3. Good:

(1) The overall performance of the machine is good. The bed body is made of high-quality and high-strength special materials. The machine tool mechanism is advanced. The key components of the machine tool equipment have good rigidity, high strength, impact resistance, small deformation, and impact resistance. . (2) The strength of the power head is high, the gear box forms a full shape, high-quality high-strength special materials, high strength and impact. The drive gear made of high-performance gear material has passed special heat treatment and precision grinding, and the gear gap mechanism is used to ensure the smooth transmission of the transmission, with high sound and high transmission efficiency. All bearings use imported high-precision, high-strength bearings, making the entire gearbox smaller, smoother and more reliable. The only optimized saw blade stabilization system can greatly increase the rigidity of the clamped circular saw blade, and more effectively reduce the vibration of the saw blade. The ostrich improves the space life of the saw blade and the accuracy is reliable.

(3) The automatic power feeding system is mainly composed of servo motor, ball screw, linear track, feeding frame, horizontal clamping cylinder, etc. The main function is to realize high-precision automatic length and automatic workpiece delivery.

4. Province:

To save materials, the circular saw manufacturer newly designed the no tailing device function according to the increasing needs of users. It is mainly through the use of a servo motor to drive the ball screw to finally achieve zero-length tail sawing, so that the tail sawing The process is completely unaffected by the clamp structure. The implementation of this function is bound to save users a lot of raw material costs, which can save as little as tens of thousands to as many as hundreds of thousands of raw materials costs each year.

Service hotline

0086-315-8198868

Contacts: Mr. Alex Sun Mobile:+8613663359375 Tel:+863158198868 Email: alexsun@torsel.net

| Contact:Nina Lee

|

Address: Puhui Street, Fengnan Economic and

Technological Development Zone, Tangshan City,

Hebei Province